WGJ-S TRIO

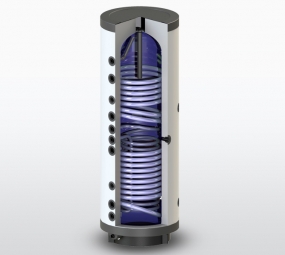

Exchangers WGJ-S TRIO are designed to heat and store hot water for the needs of flats, houses and small buildings. They are equipped with three different power supplies to the heating system.

The tank is covered inside with a layer of special high temperature ceramic enamel.

Available models:

| Catalog number | Model | EAN |

| 066-30-306 | WGJ-S FIT TRIO 300 | 5903538240571 |

| 066-40-306 | WGJ-S TRIO 400 | 5903538240908 |

| 066-50-306 | WGJ-S TRIO 500 | 5903538240915 |

| Type | Unit | WGJ-S FIT TRIO 300 | |||

| Tank capacity | dm³ | 291 | |||

| Heat exchanger area | m² | bottom | center | top | |

| 1,4 | 1,2 | 1,0 | |||

| The capacity of the coil | dm³ | 8,0 | 5,4 | 5,7 | |

| Efficiency hot water 80/10/45°C 70/10/45°C 60/10/45°C | dm³/h |

826 727 506 |

690 578 401 |

595 504 361 | |

| Heating power 80/10/45°C 70/10/45°C 60/10/45°C | kW |

33,6 29,6 20,6 |

26,4 22 16 |

24,2 20,5 14,7 | |

| Efficiency hot water 80/10/60°C 70/10/60°C | dm³/h |

450 279 |

392 248 |

326 206 | |

| Heating power 80/10/60°C 70/10/60°C | kW |

26,2 16,2 |

22,8 14,4 |

19 12 | |

| Heating water flow in the coil | m³/h | 2,2 | 1,6 | 1,7 | |

| Standing loss** | W | 73 | |||

| ErP Efficiency Class** | C | ||||

| Operating parameters of the tank | Maximum operating pressure and temperature pr = 0,6 MPa tr = 80°C | ||||

| The parameters of the heating medium | Maximum operating pressure and temperature pr = 0,6 MPa tr = 100°C | ||||

| Type of tank | steel covered inside with ceramic enamel | ||||

| Type the outer housing | plastic, steel sheet or skay | ||||

| Thermal isolation | 70 mm polystyrene foam or 60 mm polyurethane foam | ||||

| Height | isolation PS | mm | 1900 | ||

| isolation PUR | mm | 1880 | |||

| Max. altitude at an inclination | isolation PS | mm | 2010 | ||

| isolation PUR | mm | 1985 | |||

| Diameter | isolation PS | mm | 650 | ||

| isolation PUR | mm | 630 | |||

| Weight | kg | about 150 | |||

** in accordance with applicable since 26 September 2015. EU Commission Regulation No. 812/2013

| Type | Unit | WGJ-S TRIO 400 | WGJ-S TRIO 500 | ||||

| Tank capacity | dm³ | 402 | 461 | ||||

| Heat exchanger area | m² | bottom | center | top | bottom | center | top |

| 1,6 | 1,3 | 1,1 | 1,9 | 1,4 | 1,4 | ||

| The capacity of the coil | dm³ | 9,5 | 5,7 | 6,3 | 10,7 | 6,0 | 8,0 |

| Efficiency hot water 80/10/45°C 70/10/45°C 60/10/45°C | dm³/h |

948 826 600 |

762 640 462 |

629 526 378 |

1143 980 774 |

826 727 506 |

826 727 506 |

| Heating power 80/10/45°C 70/10/45°C 60/10/45°C | kW |

38,6 33,6 24,4 |

31 26 18,8 |

25,6 21,4 15,4 |

46,5 39,9 28,5 |

33,6 29,6 20,6 |

33,6 29,6 20,6 |

| Efficiency hot water 80/10/60°C 70/10/60°C | dm³/h |

523 330 |

425 268 |

354 227 |

621 392 |

450 279 |

450 279 |

| Heating power 80/10/60°C 70/10/60°C | kW |

30,4 19,2 |

24,7 15,6 |

20,6 13,2 |

36,1 22,8 |

26,2 16,2 |

26,2 16,2 |

| Heating water flow in the coil | m³/h | 2,6 | 2,1 | 1,9 | 3,0 | 1,9 | 2,2 |

| Standing loss** | W | 59 | 67 | ||||

| ErP Efficiency Class** | B | B | |||||

| Operating parameters of the tank | Maximum operating pressure and temperature pr = 0,6 MPa tr = 80°C | ||||||

| The parameters of the heating medium | Maximum operating pressure and temperature pr = 0,6 MPa tr = 100°C | ||||||

| Type of tank | steel covered inside with ceramic enamel | ||||||

| Type of the outer housing | skay type of material | ||||||

| Thermal isolation | 100 mm polystyrene foam | ||||||

| Weight | kg | about 195 | about 220 | ||||

*80°C, 70°C, 60°C - heating water temperature on the entering the coil

10°C - temperature of the water flow

60°C - temperature hot water

** in accordance with applicable since 26 September 2015. EU Commission Regulation No. 812/2013

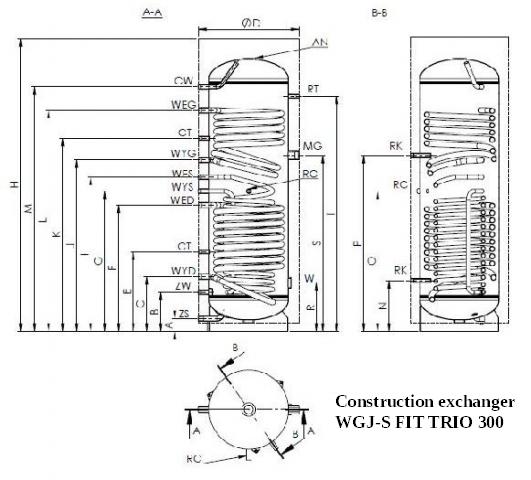

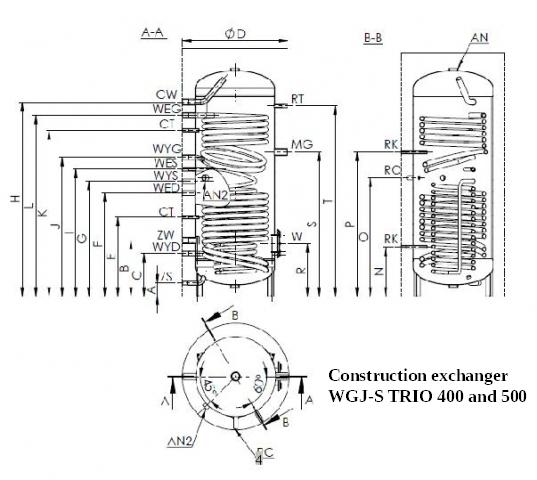

| Parameter | Unit | WGJ-S FIT TRIO 300 | WGJ-S TRIO 400 | WGJ-S TRIO 500 | |||||

| Height | H | mm | 1900 | 1850 | 2150 | ||||

| Diameter | D | mm | 650 | 810 | 810 | ||||

| CW | Hot water | M | mm | ¾" | 1570 | 1 ¼" | 1475 | 1 ¼" | 1705 |

| ZW | Cold water | B | mm | ¾" | 250 | 1 ¼" | 425 | 1 ¼" | 425 |

| RC | Circulation | O | mm | ¾" | 900 | ¾" | 900 | ¾"" | 1015 |

| RK | The capillary tube | P | mm | ½" | 1130 | ½" | 1095 | ½" | 1245 |

| N | mm | ½" | 325 | ½" | 375 | ½" | 375 | ||

| WEG | Power top coil | L | mm | 1" | 1420 | 1" | 1375 | 1" | 1605 |

| WYG | Back to the top coil | J | mm | 1" | 1100 | 1" | 1055 | 1" | 1195 |

| WES | Power center coil | I | mm | ¾" | 990 | ¾" | 965 | ¾" | 1095 |

| WYS | Back to the center coil | G | mm | ¾" | 900 | ¾" | 875 | ¾" | 1005 |

| WED | Power bottom coil | F | mm | 1" | 810 | 1" | 785 | 1" | 865 |

| WYD | Back to the bottom coil | C | mm | 1" | 350 | 1" | 325 | 1" | 325 |

| CT | Temperature sensor | K | mm | ½" | 1240 | ½" | 1260 | ½" | 1405 |

| E | mm | ½" | 510 | ½" | 600 | ½" | 600 | ||

| MG | Muff heater | S | mm | 1 ½" | 1130 | 1 ½" | 1095 | 1 ½" | 1245 |

| W | Cleaning hole | R | mm | 2" | 310 | - | - | - | - |

| W | Cleaning hole 133/166/195 | R | mm | - | - | 400 | - | 400 | |

| ZS | Drain | A | mm | ¾" | 80 | ¾" | 100 | ¾" | 100 |

| AN2 | Magnesium anode on the cork 1 ¼" - bottom | mm | - | Ø 30 x 200 | Ø 30 x 270 | ||||

| AN | Magnesium anode on the cork 2"- top | mm | Ø 40 x 430 | Ø 40 x 500 | Ø 40 x 500 | ||||