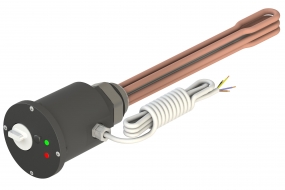

Heater EJK MAXI

Heaters type EJK maxi version are used to heat water in open and closed tanks made of metal, in particular in enamel tanks for hot water. In those reservoirs protected against corrosion with cathode method of magnesium anodes, heating elements should be partly or completely electrically isolated from the walls of the tank. As a result, the electrochemical potential difference in filled with water tank between the heating elements made of copper or a special stainless steel and the container made of carbon steel, partially leveled. This significantly increases the service life of the heating element and magnesium anode lifetime.

In heaters type EJK maxi version heating elements are placed in the head of metal. For the partial merger between heating element and tank combines grounding resistor with properly selected resistance, which includes these elements for cathodic corrosion protection of the tank. This solution gives several advantages: protects electric heater inside enamel tank against electro-chemical corrosion, while maintaining the tank cathodic protection and magnesium anode lifetime.

| Heater type | Power | Voltage supply | The length of the dead zone | The length of immersion to seals | Threaded connection | Minimum volume of the tank |

| kW | V | mm | mm | inch | dm³ | |

| EJK 3000 | 3,0 | ~ 400 | 100 | 290 | 1½" | 80 |

| EJK 4500 | 4,5 | ~ 400 | 100 | 390 | 1½" | 100 |

| EJK 6000 | 6,0 | ~ 400 | 100 | 500 | 1½" | 100 |

| EJK 9000 | 9,0 | ~ 400 | 100 | 720 | 1½" | 250 |

| Heater type | Power | Rated current | Minimum cross-wires the power cord | Type of gland in the housing of the heater | The diameter of the power cord |

| kW | A | mm² | mm | ||

| EJK-3000 | 3,0 | 4,3 | 1,0 | PG 13,5 | 6,0 ÷ 12,0 |

| EJK-4500 | 4,5 | 6,5 | 1,0 | PG 13,5 | 6,0 ÷ 12,0 |

| EJK-6000 | 6,0 | 8,7 | 1,5 | PG 13,5 | 6,0 ÷ 12,0 |

| EJK-9000 | 9,0 | 13,0 | 1,5 | PG 13,5 | 6,0 ÷ 12,0 |